In 2022, the worldwide market value for cement production was estimated at around 322.9 billion EUR, with an anticipated annual growth rate of 6.11%.[1] The global pandemic has influenced the industry significantly, as cement production experienced a plunge in demand by around 3.6%. Nevertheless, as the interest in construction projects is steadily increasing, the need for concrete is building up.[2] As the world learned to adapt to the constant health challenges, and production and trade slowly picked up, there has been a global demand for both residential and non-residential buildings, as well as public infrastructure, making the future expansion of the construction sector an everlasting trend.

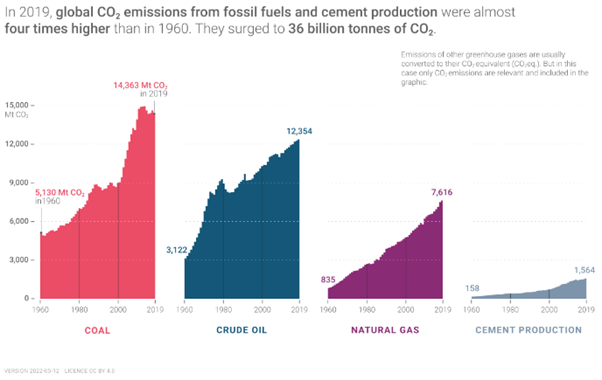

However, the production of cement, a key ingredient in concrete production, does not come without its disadvantages and negative impacts, especially when it comes to the environment. If we were to consider the cement industry as a country, it would be ranked the fourth largest greenhouse gas (GHG) contributor worldwide, being responsible for 7-8% of global CO2 emissions.[3] Climate actions targeting the reduction of GHG emissions, especially CO2, are a top priority for reaching carbon neutrality by 2050 and are the core objective of the European Green Deal.[4] Putting these numbers into context, even though a concrete mix only requires 10-15% cement, this accounts for 90% of the total GHG emissions of concrete.[5] Alongside CO2, the cement industry also generates SO2, NOx and dust emissions, all causing severe respiratory and cardiovascular problems.

On the path towards decarbonising the cement industry, one must also take into consideration not only the most pressing climate goals but also the fact that cement still has no perfect or near-perfect substitution in the industry. Therefore, more environmentally friendly and sustainable ways must be invested in cement production in order to minimize pollution and environmental degradation.

Why is cement production a carbon-intensive activity?

Cement does not occur naturally. To manufacture it, a combination of eight main ingredients is required. These ingredients are taken from limestone, clay, marl, shale, chalk, sand, bauxite, and blast furnace slags. The most common way to manufacture cement is through a dry method. The first step is to quarry the main raw materials (limestone, clay, and others). After quarrying, the rock is crushed in several stages. The first crushing reduces the rock’s size, which then goes to secondary crushers or hammer mills for further reduction. The crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kiln.[6] The mined, crushed, dried and grinded materials are sent into the kiln through a preheater system bringing it up to 1,400 Celsius. The resulting product clinker is then grinded with additives until the final product is a fine and clean powder. [7] The carbon-intensive way to produce cement is based on two pillars: combustion and process emissions. Burning fossil fuels (such as coal and petroleum coke) are used in bringing the raw materials to the desired temperature. The use of fossil fuels generates 40% of CO2 emissions. During the heating process, the limestone also releases additional levels of CO2 emissions.

Figure 1. Global CO₂ emissions with cement production being the fourth largest polluter. Source: Facts on climate 2019[8]

The cement industry in Azerbaijan

Azerbaijan has a growing cement industry, with three integrated cement plants that can produce 4.7 Mt per year. Here, the cement sector has been developing as a result of the increasing construction activities in the country and the demand for cement in both domestic and regional markets.[9] Azerbaijan’s strategic location also allows it to export cement to neighbouring countries in the Caspian region and the Caucasus. Countries such as Georgia, Russia, Turkmenistan, and Kazakhstan are potential markets for Azerbaijani cement exports.[10] In the first half of 2023, the total national cement production was around 1.76Mt, according to the State Statistics Committee. This corresponds to a 1.9% year-on-year rise from first-half 2022 levels.[11]

LACHIN-1 LLC

Placed in the Garadagh region, LACHIN-1 LLC is a cement-producing enterprise that annually delivers around 38,000 tonnes of products. It produces several concrete mix grades, such as AS-CEMENT 300 M, AS-CEMENT 400 M, SPESİFİK 500 M, ULTRA PROFLEX, and ULTRA PRORAPİD. Furthermore, even though the plant does not produce the clinker itself, it buys it from other manufacturers. During the RECP monitoring visits, the interest of the company has been directed towards identifying ways to improve its overall production, mainly by reducing raw material losses at every stage.

SHAMKHAL-86 LLC

SHAMKHAL-86 LLC is a concrete-mix producer based in a region near Mingachevir. It produces the following concrete mix grades: M100, M150, M200, M250, M300, M350, and M400. Concerned with its environmental performance, SHAMKHAL-86 LLC was interested to join the UNIDO RECP Demonstration Project to address its concerns about the impact of the production processes on the environment. As well, the company was also looking into means to increase savings and improve overall occupational safety and health parameters for its workers (considering the dust released when the raw material is unloaded).

NORM OJSC

NORM OJSC is a cement manufacturer situated in the region of Garadagh. It produces up to 2,500,000 tonnes of cement per year, focusing on various types: clinker, A,B,C,S,D CEM, and cement for plugging wells. The company is mainly focused on the domestic market. Currently, it aims to take advantage of the RECP Demonstration Project to use its raw materials in accordance with the existing regulations, as well as to introduce alternative fuels that could be less pollutant.

To make their production processes more sustainable, LACHIN-1 LLC, SHAMKHAL-86 LLC, and NORM OJSC have all decided to take part in the UNIDO RECP Demonstration Project under EU4Environment. Throughout 2022, the RECP project team had the chance to visit these Demonstration Companies on multiple occasions in order to conduct relevant inspections, as well as measurements of the relevant parameters. These activities helped the RECP expert identify and adapt the RECP measures to help the companies optimize their use of resources, and better manage the waste excess. Once the RECP team completes the resource efficiency reports for each company, the findings will empower the cement producers to lessen their adverse environmental impact, enhance their efficiency, and gain a competitive edge. Moreover, they will actively contribute to promoting circular and sustainable approaches in cement production within their regions as well as nationwide.

Back to the ‘Greening the Industry’ campaign in Azerbaijan.

Back to the ‘Greening the Industry Campaign’ in the Eastern Partnership.

[1] https://www.researchandmarkets.com/reports/5743072/cement-market-global-industry-trends-share#product–toc

[2] https://www.fortunebusinessinsights.com/industry-reports/cement-market-101825

[3] https://www.nrdc.org/bio/veena-singla/cut-carbon-and-toxic-pollution-make-cement-clean-and-green

[4] https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2050-long-term-strategy_en

[5] https://www.nrdc.org/bio/veena-singla/cut-carbon-and-toxic-pollution-make-cement-clean-and-green

[6] https://www.cement.org/cement-concrete/how-cement-is-made

[7] https://www.howden.com/en-us/articles/cement/how-is-cement-made#:~:text=Cement%2C%20like%20flour%2C%20is%20an,an%20impenetrable%20rock%2Dlike%20mass.

[8] https://factsonclimate.org/infographics/fossil-fuels-emissions

[9] https://www.researchgate.net/profile/Latafat-Gardashova/publication/309179542_httpwwwijeracompapersVol6_issue10Part-1F06101032038pdf/links/5949fff0a6fdcc3e17fc7b4e/http-wwwijeracom-papers-Vol6-issue10-Part-1-F06101032038pdf.pdf

[10] http-wwwijeracom-papers-Vol6-issue10-Part-1-F06101032038pdf.pdf (researchgate.net)

[11] Azerbaijan’s cement production rises in the first half of 2023 – Cement industry news from Global Cement