Read in Georgian.

Cheese is an ancient food with origins long predating recorded history. Whereas there is no clear evidence pinpointing the exact origin of cheese making, it is assumed that the product came about with the domestication of sheep, around 8000 BCE.[1] Cheese is a staple food in everyday consumption due to its high content of fat, protein, calcium, and phosphorus, alongside its versatility and affordability.[2] Currently, more than a thousand types of cheese exist worldwide. They vary by style, flavour, ingredients, textures, and means of production; based on such criteria, cheeses range from soft to hard (having a long storage life, especially when encased in a protective rind).

In the past decade alone, the growing demand for cheese products has led to a steady increase in cheese production, which reached approximately 22 million tonnes in 2021.[3] Despite the COVID-19 pandemic and its related limitations, cheese production continues to grow, and developing countries, such as Georgia, are beginning to engage more with external markets, both domestic and international.

Today, cheesemaking is mostly accomplished in commercial facilities, taking an industrial approach. Georgian producers, while not as well-established as their Western counterparts, provide a wide array of cheese products to the global markets. Georgia’s cheese production includes 14 different local varieties of cheese. In 2020, the country exported 59 tonnes of cheese (compared to 46 tonnes in 2019), which brought profits of almost €500,000 (1.4 mln. GEL).[4]

The multistep process requires acute control of quality, precise measurements, and technological finesse. Industrial cheese-making also demands significant consumption of thermal energy and electricity, as well as large quantities of water used for cleaning.

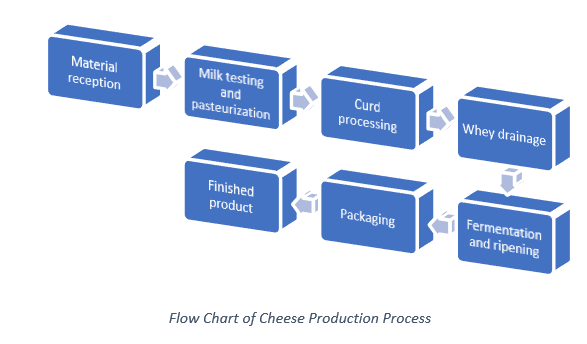

The production starts with the reception of fresh milk from farmers or that produced in enterprise-owned farms. This is stored on-site, tested for acidity and fat contents in a laboratory, and then pasteurized. The process can be energy intensive, as the milk needs to be heated up and then homogenized under high temperatures (60-70°C).

After pasteurization, the milk is inoculated with starter cultures, and, during the fermentation process, acid is produced. This also aids the ripening, where the milk’s temperature varies between 30-37°C.

The next steps involve coagulation, which transforms the milk into curd in a gel-like state. It is then followed by the separation of the liquid from the solid fraction. The liquid fraction, the whey, consists of water, lactose, and proteins, and can be reused and repurposed for the production of other dairy outputs (such as yoghurt, butter, bread, commercial pastry, or animal feed). After the whey has been drained, the cheese can be further fermented and salted, after which it is left to ripen. The ripened product is then packaged and released for sale.

“Tsivis Kveli” Ltd. working to improve its resource efficiency

One of the leading Georgian cheese producers is “Tsivis Kveli” Ltd., a mid-sized company based in the village of Kurdghelauri, Telavi Municipality. The enterprise produces 70 different types of cheese (such as Guda, Sulguni, smoked Sulguni, etc.) which account for up to 110 tonnes of cheese per year. These are then distributed both across the country (in large cities such as Tbilisi and Batumi) as well as on international markets. Intermediate products are also carefully reused, with “Tsivis Kveli” repurposing its whey for the production of Nadughi (a local dairy product) and as feed for animals. The company is also an important contributor to the local economy, as it employs around 50 workers during peak production capacity and relies on local producers for raw milk and other complementary products.

“Tsivis Kveli” was interested in adopting more sustainable and energy-efficient practices to reduce its thermal energy consumption, as well as optimize electricity use and thus resource efficiency. To do so, the company joined the UNIDO Resource Efficient and Cleaner Production (RECP) Demonstration Project under EU4Environment. Between 2021 and 2022, RECP experts evaluated the main site of the enterprise and identified key gaps and resource and energy losses in the production line. Subsequently, experts were also able to suggest two relevant RECP measures to reduce energy consumption and improve technology. As a result, the most energy-intensive on-site equipment (steam boilers and water heaters) will require less energy and less fuel to operate, and will provide both financial and environmental benefits, significantly reducing the carbon footprint of the company.

Currently, “Tsivis Kveli” consumes around 20,000 m3 of natural gas for its thermal processes. To reduce the heat consumption for the pasteurization process, the company was recommended to collect and reuse the condensed steam for the boiler. This way, the recirculation of the condensed steam through the pasteurization system can decrease natural gas consumption by 10%. To implement this measure, the company would require a relatively low investment in the amount of €726 (2,050 GEL) which the company can easily implement using its own financial sources. The annual energy savings would also be about 19 MWh. Compared to the current consumption and annual financial savings of €933 (2,635 GEL), the annual CO2 emissions would decrease by about 3.7 tonnes per year. The additional benefits the company can achieve are the extension of the lifetime of the steam boiler (with an average price of €8,860 (25,000 GEL) and the reduction of annual maintenance cost (about €106 (300 GEL) per year).

The company’s motivation and commitment to a more sustainable production model will also lead it to become a successful example for other SMEs in this sector, in Georgia, as well as the EU’s Eastern Partnership (EaP) region.

Back to ‘Greening the Industry’ campaign in Georgia.

Back to the ‘Greening the Industry Campaign’ in the Eastern Partnership.

[1] Source: https://www.mdpi.com/2072-6643/7/9/5340

[2] Source: https://www.journalofdairyscience.org/article/S0022-0302(17)31054-8/fulltext

[3] Source: https://www.statista.com/statistics/1120911/cheese-production-worldwide/

[4] Source: https://www.selinawamucii.com/insights/market/georgia/cheese/