Read in Georgian.

The early history of juices pinpoints 16th-century Italy as the possible birthplace of the modern version of lemonade. Like so many of the beverages we drink today, lemonade is a cool, refreshing choice that has remained popular, versatile (being consumed on its own or in different mixes), and accessible throughout the years. Lemon juice is also a popular non-alcoholic choice for those who enjoy and seek the sour taste of lemons and a high concentration of citric acid that can be sweetened with sugar, syrup, or honey. In the past 100 years, important innovations have taken place in the juice industry. From the invention of carbonation techniques in the 1760s that utilized chalk and acid, to the emergence of soft drinks and pasteurization processes, the popularity of juice concentrates (including lemonades, limeade, orangeade, and so on) has boosted ever since.[1]

In Georgia, lemonades made from natural syrups and pure spring water have become a staple drink (at feasts or for special occasions) alongside popular foods and snacks. Here, the production of lemonade started with the work of Mitrofan Lagidze, an experienced pharmacist who experimented with fruits and aromatic herbs. By 1887, he managed to create a drink that quickly grabbed the attention of the local residents. [2] This drink was “Lagidze Waters”, and it was based on soda and a variety of natural syrups, which helped it become a popular soft drink. Thanks to it, Mitrofan Lagidze became well-known for his invention and products, with the technology and culture of “Lagidze Waters” being inscribed on the UNESCO Intangible Cultural Heritage of Georgia list in 2014.[3]

Nowadays, Lagidze descendants manufacture the drink under the name “MITROFAN LAGIDZE 1887”, priding that the lemonade recipe is a well-kept secret. Varieties of this product include three main flavours: tarragon, lemon, and pear. While big soft drink producers like “NATAKHTARI”, “ZEDAZENI”, “ZANDUKELI”, or “Georgia’s Natural Organic” market their beverages both domestically and internationally, the lemonade produced by small companies throughout the country is primarily sold on local markets.

In Georgia, the export of soft drinks has witnessed a steady increase from 2019 until 2022, going from 46 mln. litres per year to 122.8 mln. litres per year.[4] The expected annual revenue from non-alcoholic beverages is predicted to reach 297.7 ml EUR in 2023, and an annual market growth of 5.66% (CAGR 2023-2027).[5] As a result, local soft drink producers are presented with both new challenges and opportunities, as they work to boost production to satisfy the growing demand and invest in new products to benefit from the rising global competition.

This is also the case of LLC “Neqtari”, a lemonade producer from Telavi, Kakheti. With an annual production of up to 5,500 tonnes of lemonade, “Neqtari” sells all its products locally and regionally. The company is currently producing eight varieties of lemonade, with plans to expand its range in the near future. The lemonade is bottled in 0.5 litres, 1 litre, and 2 litres plastic bottles. The production cycle starts by placing the raw materials into storage. These raw materials contain a variety of ingredients (such as flavours, dyes, sugar or other sweeteners, citric acid, sodium benzoate, and carbon dioxide). By adding water, the syrup is formulated and consequently mixed with water to generate the soft drink. Water is also used for the PET bottles moulding. The lemonade is then transferred to the pasteurization unit, where it is prepared for filling. This is achieved in pre-prepared clean bottles. Afterwards, it is necessary to inject carbon dioxide for gasification. The injected bottles are capped and made ready for packaging, with the final product being stored in the storage unit and sorted for distribution.

In addition to the lemonade production, the company also manufactures disposable plastic utensils using granulated plastic. For the production cycle of disposable plastic tableware and packaging materials, granules are heated to the melting temperature using electric heaters. Here, the temperature varies, depending on the type of production. Then a thin coating of the molten grains is rolled on the drum. This generates plastic films which are used for making trays, bags, and cups. The cut offs are then moved to the shredder, which granulates them once again. Shredded film granules are reused to produce the same plastic film. Hence, according to the current technological cycle, the enterprise utilizes all raw materials without generating waste.

In the near future, the company aims to increase its production capacity and enter new markets. The need to optimize production, as well as the desire to reduce energy consumption have both motivated LLC “Neqtari” to join the UNIDO Resource Efficient and Clean Production (RECP) Demonstration Project under EU4Environment. To decrease electricity consumption and associated annual costs, the company was recommended to install a 540-kW capacity Photovoltaic plant (PV) and connect it to the grid. “Neqtari” implemented this measure in 2021, investing 1,2 ml GEL (314,630 EUR)[6]. Now, the solar plant generates 693,474 kWh of electricity per year, which exceeds the company’s current consumption (473,390 kWh per year). Annual savings also amounted to 145,700 Gel. (38,201 EUR), while the annual generation of CO2-eq emissions was reduced to 47 tonnes.

Still, a main challenge for the company remains the high energy consumption during heating or melting of the plastic granules. The mechanical system used to produce the plastic film must become more energy-efficient, and the production process must be optimized.

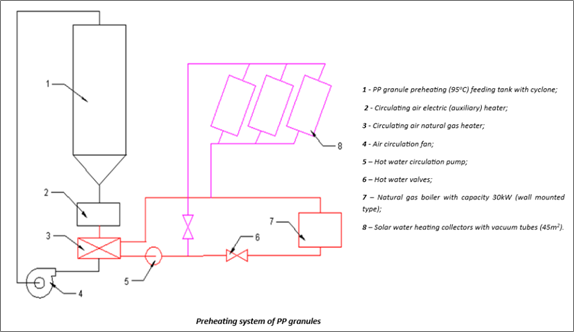

In this case, the RECP assessment recommended a measure that, if implemented, would increase energy efficiency, lower the annual energy costs, and further reduce CO2-eq emissions. This recommendation foresees the installation of a preheating system for the PP (polypropylene) granules, working on natural gas as the general heating source or, even more, installing a hybrid preheating system.

For the implementation of the first option, the company would need about 6,000 GEL (1,570 EUR). This would lead to savings of about half of the entire annual energy costs for melting the PP granules, as natural gas is less expensive. The measure’s basic payback period would be 1.3 years. Though, as the natural gas boiler is less efficient than the electric heater (only 90% of the performance of the electric one), there are no benefits in terms of reduced CO2-eq emissions or reduction of total energy consumption.

For the implementation of the second option, the company would need to invest about 62,300 GEL (approx. 16,335 EUR). The advised measure would result in a 91% reduction of energy costs for melting the PP granules. The payback period for the measure would be of 6.5 years, and, in addition to the financial advantages, the suggested measure could also result in a reduced annual demand of energy (14,175 kWh/year or, 1,624 m3 of natural gas) and a reduction in CO2-eq emissions (approximately 2.9 tonnes per year).

Back to ‘Greening the Industry’ in Georgia

Back to the ‘Greening the Industry Campaign’ in the Eastern Partnership.

[1] Wolf, A., Bray, G.A. and Popkin, B.M., 2008. A short history of beverages and how our body treats them. Obesity reviews, 9(2), pp.151-164.

[2] https://madloba.info/en/blog/pro-gruziyu/gruzinskaya-kuhnya/luchshij-gruzinskij-limonad/

[3]https://www.culturepartnership.eu/upload/editor/2017/Research/170926%20CDIS%20Georgia%20Analytical%20and%20Technical%20Report.pdf

[4] https://www.geostat.ge/en/modules/categories/297/food-security

[5] https://www.statista.com/outlook/cmo/non-alcoholic-drinks/georgia

[6] Average exchange rate for 2021 EUR/GEL for 2021- 3.8140 Source https://www.geostat.ge/en/modules/categories/92/monetary-statistics