Read the article in Azerbaijani.

Since its creation in 2018, Global Recycling Day has been a means to emphasize the importance of recycling and conservation by educating individuals worldwide about the status of our essential resources.

Global Recycling Day, celebrated on March 18, is a recycling initiative that encourages everyone to look at waste in a new light. There are several ways to recycle that allow some materials to be reused multiple times. Recycling is also crucial for the environment because it lessens the energy we use, enhances the quality of water and air, and combats climate change.

It also reduces the usage of new raw materials, helping manufacturers save money and important resources. At the household level, newspapers, plastic water bottles, soda cans, cereal boxes, and milk cartons are some of the most common everyday recyclable items. At the industry level, different types of waste can become new or by-products when employing the right methodologies (such as PEF) to minimize waste and boost recycling.

Background

Product Environmental Footprint (PEF) is a common Life Cycle Assessment (LCA) science-based methodology that quantifies all the environmental impacts over the entire life cycle of a product. This includes product-related emissions into water, air or soil, as well as resource use and depletion, the impact of land and water usage, and so on.

However:

- PEF is more stringent in its rules than a ‘normal’ LCA, as it is a detailed prescribed method for analysis.

- The PEF method and its database offer consistency, making it suitable for comparing products within the same product groups.

Moreover, the PEF and Organisation Environmental Footprint (OEF) methods provide guidance for the collection and modelling of inventory data (including allocation rules for recycled materials as well as data quality requirements). In a nutshell, while PEF and LCA are used for calculating the impact of a product over its lifetime, PEF is more clearly defined and, thus, could become the ‘gold standard’ for LCAs in Europe.

For example, PEF defines clear system boundaries for a product’s lifecycle, whereas LCA boundaries are open to interpretation. PEF also provides rigorous guidance for assessing end-of-life, which LCA does not require. PEF is standardized for comparability between products, whereas the scope of an LCA can differ depending on who is conducting the assessment. This is an important distinction, as comparability is only possible if the results are based on the same rules (reason for which the Product Environmental Footprint Category Rules (PEFCR) exist). PEFCR are PEF’s ‘Category Rules’ for individual product groups, offering step-by-step guidance on conducing PEF for different kinds of products. These category rules make PEF ideal for achieving consistent and comparable environmental impact reports across industries, ensuring that every product’s impact is calculated in the same standards and that consumers can accurately compare goods within the same category.

Steps to establishing a product’s environmental footprint (EF)[1]

Steps of the EF method

1 – EF Goal and Scope Definition

2 – EF Inventory Analysis

3 – EF Impact Assessment

4 – Interpretation and Reporting

5 – Verification and validation

A default set of 16 impact categories belongs to the first step. Then, the second step includes inventory modelling, circularity, data collection, and quality requirements. In the third step, the impact assessment in the EF methods is realized. During this step, the impact categories go through technical phases which include classification, characterization, normalization, weighting and interpretation. The last two steps include interpretation and reporting, and verification and validation.

An inventory of all input and output, elementary (resources, emissions) and nonelementary (energy, waste, materials) flows shall be compiled for all processes included in the value chain. All flows have to be modelled until the elementary flow level is ready to calculate the associated impact of the life cycle of a product or organization (e.g. from the output waste or when the specific air, water and soil emissions generated by the treatment processes are determined).

The mandatory life cycle stages included in an EF study are:

- Raw material acquisition and pre-processing: e.g., extraction of resources, preprocessing of all materials (including recycled materials), agriculture, forestry, packaging production, and transportation associated with these activities.

- Manufacturing: all processes taking place from the entry to the exit gate of the production facility (e.g., chemical processing, manufacturing, assembly).

- Distribution: transport and storage of the finished product(s), including the refrigeration and warehouse activities consumptions (e.g., energy).

- Use stage: product(s) use for the defined function and lifetime, including all necessary inputs (e.g., energy, maintenance materials, coolant).

- End of life: all activities occurring from the moment the product ceases to perform its function and is disposed or recycled. This includes collection and transport, dismantling, sorting, processing into recycled material, landfill, and incineration. [3]

Circular Footprint Formula (CFF)

One crucial aspect of an inventory analysis in LCA studies is to accurately and consistently model waste and recycled materials, and to allocate environmental burdens and credits to users and producers of such flows. In this sense, the PEF and OEF methods provide an approach that has been developed through a dedicated consensus-building process: the Circular Footprint Formula (CFF). All waste flows produced during the manufacturing, distribution, use, and end of life stage shall be modelled according to this formula, as well as all recycled or recyclable material entering or leaving the system (i.e. recycled material used in the manufacturing stage and recycling of material from the product’s end of life).

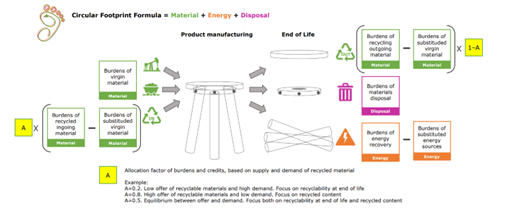

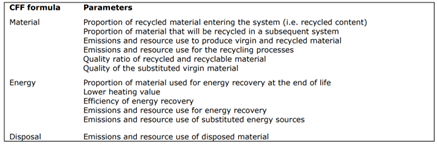

The CFF is built up on three parts, namely a material, energy, and a disposal formula (Figure 1 and Table 1. Parameters of the Circular Footprint Formula). Summing up their results will then give the overall number of emissions and resources that belong to the system’s inventory (recycling, disposal, and energy recovery processes).

The material part of the formula applies to all stages of the value chain where recycled materials substitute raw materials. The formula addresses the need of a consistent method to allocate environmental burdens (and credits) to suppliers and users of recycled materials, and it is based on market characteristics. The underlying rationale of this formula is that when there is a low offer and high demand of recyclable materials, more credits are attributed to the production of recyclable materials (i.e. manufacturers that enable recycling of materials at the end-of-life benefit from lower environmental burdens). On the contrary, when there is high availability and low demand, more credits are given to users of recycled materials.

The energy part of the formula relates to the quantity of material that is used for energy recovery at the end of life. In this case, credits are attributed to energy recovery, corresponding to the avoided emissions and resource use of the substituted energy sources. Finally, the disposal formula calculates emissions and resource use related to the disposal of all materials that are not recycled or used for energy recovery.

Example on a fictive product, showing the basic elements included in the circular footprint formula are illustrated in the Figure 1 below: [4]

Figure 1

Table 1. Parameters of the Circular Footprint Formula [5]

Recycled content values must be specific to the supply chain or the application. To ensure transparency in the calculation of recyclable materials and recycling output rate, recyclability shall be evaluated and declared, based on company or industry data. In addition, including a quality parameter allows a manufacturer to capture multiple recycling loops, including downcycling (i.e., obtaining materials of lower quality than the originals). Default, sector-specific values of the CFF parameters are provided in a document that can be used when company-specific values are not mandatory and company-specific data are not available.

The CFF is meant to quantify the inventory of resources used and emissions associated with recycled content, recyclability, disposal, and energy recovery.

All in all, recycling is a crucial aspect for the environment as it conserves essential resources, reduces the use of new raw materials, and combats climate change. On top of it, methodologies based on a product’s life cycle assessment (such as PEF) can help enterprises further quantify environmental impacts, including the impact of using recycled materials in the manufacturing process.

[1] https://ec.europa.eu/environment/eussd/smgp/pdf/EF%20simple%20guide_v7_clen.pdf

[2] https://www.cramogroup.com/en/cramo-and-circularity-2/

[3] https://www.green-care-professional.com/international/circular-economy/

[4] https://ec.europa.eu/environment/eussd/smgp/pdf/EF%20simple%20guide_v7_clen.pdf

[5] https://ec.europa.eu/environment/eussd/smgp/pdf/EF%20simple%20guide_v7_clen.pdf