Read in Georgian.

Believed to originate in Persia, with cultivation quickly spreading throughout the Mediterranean, Caucasus, and Middle East, all the way to India and China, pomegranate is one of the world’s most ancient fruits, holding a rich and fascinating history. Named “pomum granatum” (apple of many seeds), pomegranate has long been imbued with rich symbolic and cultural value. [1] The fruit is also an important source of bioactive compounds used for centuries in folk medicine. Its juice has been demonstrated to be high in antioxidant activity and effective in the prevention of several illnesses such as atherosclerosis.[2] The seeds contain carbohydrates, tannins, vitamins, and citric acid, whilst the juice can treat gastrointestinal and cardiovascular diseases. Used for seasoning, as a garnish, or even as the primary cooking liquid, pomegranate plays an important role in the diet and cooking of the Middle East, India, and the Caucasus.[3] It has a positive effect on liver and kidney function, regulates prothrombin in the blood, restores blood, and promotes wound healing. The tree can also be utilized as a living fence, to reinforce the soil on slopes, or in decorative gardening.

The culture of using pomegranates as food also holds deep origins in Georgia. This is confirmed by both archaeological evidence as well as the distribution of pomegranate varieties spread across the country. This shows that Georgia is one of the original pomegranate centres alongside the Middle East countries.

Despite the fact that pomegranate has a great historical past in Georgia, it is mostly found on family farms, with the industrial potential still remaining untapped. The pomegranate culture is mostly spread in Western Georgia, but high-quality products are obtained in the Eastern, dry, subtropical regions. There, pomegranates find favourable conditions in some of the districts of outer Kakheti and Kvemo Kartli however, the pomegranate fruits are produced in insignificant quantities and cannot fully meet the needs of the population.

From an economic point of view, processing pomegranate is a rather profitable enterprise due to the abundance of the fruit and the fact that the costs for cultivating it can be recovered in a short timeframe. Pomegranates bear fruit in the second or third year after being planted and reach full fruit after 6-7 years. The maximum harvest is obtained at the age of 10-20 years; with a tree bearing 25-30 kilograms of fruit per year, on average.[4]

These important features and advantages have also prompted LTD Mixo’s Gardens to produce pomegranate juice since 2020. Located in Dedoplistskaro, in the Kakheti region, the company produces pomegranate juice using a handcrafting technique. The product’s major market is Georgia (specifically, the Kakheti region and Tbilisi), where the juices can be found at “Goodwill” and numerous other supermarkets (Spar, Ioli, etc.).

The company owns around four hectares of land with the potential to harvest about 100 tonnes of pomegranate each year. Currently, only one hectare (which can produce roughly 25 tonnes of pomegranates per season) is being used by the enterprise. About 70% of the pomegranate used for processing ends up as waste, while the remaining 30% becomes pure juice. In this context, the company currently generates about 7.5 tonnes of juice per year. After remodelling its production process thanks to the recommendations received as a result of the Resource Efficient and Cleaner Production (RECP) assessment conducted by UNIDO experts, the company now intends to boost its annual manufacturing capacity by 20%.

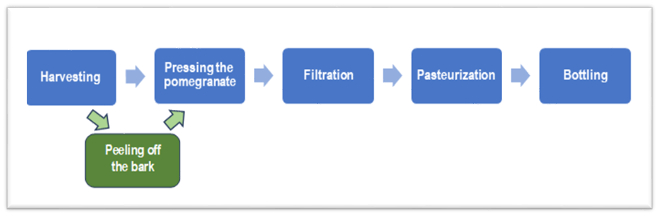

The current (handicraft) method of production includes the following processes: harvesting, pressing the pomegranate, filtration, pasteurization, and bottling. Presently, the pressing of the whole pomegranate is carried out without separation of the external bark (which has a negative impact on the overall flavour and quality of the juice). Additionally, pasteurization is carried out following mechanical filtering in an ineffective (handmade 300 l pot) utilizing a simple gas stove and direct heating (with an unstable temperature of 87–90°C). As a result, to produce 300 litres of juice, the current energy requirement for the pasteurization process is roughly 20 m3 of natural gas.

Fig.1 Suggested modification to improve the pomegranate juice production (green box)

In order to optimize energy consumption for the pasteurization process and increase the production capacity and quality of the juice, the company plans to separate the external bark of pomegranate and, after filtration, pasteurize the juice at around 78-800C in a well-insulated continuous pasteuriser.

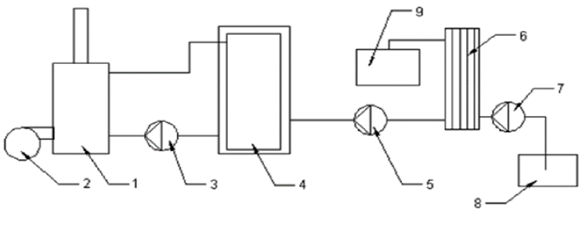

Based on estimates, the annual production of the enterprise would increase to 30 tonnes of juice per year, which means that the company will annually consume about 2,000 m3 of natural gas if the pasteurization method remains the same. In the pasteurization process, energy consumption per product can be dramatically reduced by increasing energy efficiency from 20% to 70%-80%. This is done by employing an energy-efficient boiler with a high-speed heat exchanger. A thermally insulated hot water tank could maintain approximately 1000 C of hot water produced by the (biomass/gas) boiler. The high-speed heat exchanger would then recirculate the stabilized 100o C water from the hot water tank through the hot water pump. On the other side, the freshly filtered pomegranate juice would proceed through the same high-speed heat exchanger, which would simultaneously heat the juice to the desired temperature (78–800C). Then, the pasteurized juice would be collected in a juice collector tank with a hot water jacket.

Fig.2 Recommended pasteurization process flow for pomegranate processing

- Natural gas/biomass boiler

- Burner

- Hot water circulating through pump #1

- Hot water circulating through pump #2

- High-speed heat exchanged

- Juice supply through pump #3 with frequency regulator

- Fresh juice supply tank

- Pasteurized juice collector tank (with hot water jacket)

After implementing the recommended measures (either of the two given RECP options) the annual energy savings would be more than 14 MWh (compared to the current consumption), which is about 11,000-13,000 GEL (3,572-4,222 EUR)[5]. Both RECP options have a short payback period of roughly one season (maximum two months) and would curb the annual CO2-eq emissions by about 3-4 tonnes per season.

It is worth noting that besides the biomass waste resulting from the pressed (squeezed) pomegranate, the company also holds additional biomass potential generated from the pruning (cuttings) of the pomegranate trees. The total biomass potential of the company is therefore significantly higher than its own need for production processes, so the surplus could be used to produce other types of fuels like pellets or briquettes.

Back to ‘Greening the Industry’ in Georgia

Back to the ‘Greening the Industry Campaign’ in the Eastern Partnership.

[1] https://www.nytimes.com/1979/10/31/archives/pomegranates-rich-in-history-and-taste.html#:~:text=THE%20pomegranate%2C%20one%20of%20the,apple%2C%E2%80%9D%20the%20alternate%20appellation

[2] https://www.researchgate.net/profile/Changjiang- Guo/publication/223779511_Evaluation_of_antioxidant_properties_of_pomegranate_pulp_extract/links/5a268f68aca2727dd8822227/Evaluation-of-antioxidant-properties-of-pomegranate-pulp-extract.pdf

[3] https://www.nytimes.com/1979/10/31/archives/pomegranates-rich-in-history-and-taste.html#:~:text=THE%20pomegranate%2C%20one%20of%20the,apple%2C%E2%80%9D%20the%20alternate%20appellation

[4] Source: https://agronews.ge/brotseuli-shemosavliani-kulturaa/

[5] Average exchange rate for EUR/GEL for 2022- 3.0792 Source https://www.geostat.ge/en/modules/categories/92/monetary-statistics